PTFE Rotary Seals

Benefits of Spring-energized PTFE Rotary Seals

- Spring energized seals replace conventional elastomeric O-rings and U-cups where the service conditions are beyond their operating capabilities

- Self-lubricating and can be used in dry environments

- Wide operating temperature range from -452°F (-270°C) to 600°F (288°C)

- Pressure conditions from high vacuum to high pressure (1,000 psi)

- Excellent chemical compatibility

- Designed, engineered and machined to fit

- Used where space is premium

- The spring enhances performance by:

- Allowing for tolerance variation and run-out

- Overcoming thermal expansion/contraction

- Compensating for wear to increase the useful life of the seal.

A face seal, or also known as spring energized face seal or axial seal, is specifically used when sealing off internal or external pressure or media, such as liquid or gases between two perpendicular mating parts, the pressure or media will energized the sealing lips with initial contact sealing pressure coming from the spring energizer.

One of the primary service types for face seals is oscillating or slow moving dynamics. They are used in static or dynamic machinery and connectors where maintaining consistent contact pressure in cryogenics or wide thermal cycle range applications for pumps, valves, motors, and engines is required to prevent leakage throughout the product life cycle.“

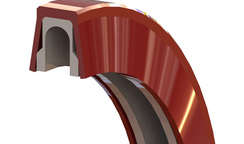

What are Duruseal® Spring-energized PTFE Rotary Seals?

Spring Energized Rotary Duruseals® are composed of a Duron® seal jacket and an energizer. Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene. We offer a wide range of Duron® and energizer materials, as well as configurations to satisfy your conditions and parameters. For a complete proposal, submit a request for quote and we will respond, immediately.

|

Duruseal® F: Finger Spring Rotary Seal | Finger spring engineered seal are suited for sealing viscuous media as the load is applied to the edge of the sealing lips. |

RFQ |

|---|---|---|---|

|

Duruseal® H: Helical Spring Rotary Seal | Helical spring engineered seal are suited for slow service, cold and vacuum service. |

RFQ |

|

Duruseal® ACF: Angled Coil Spring Rotary Seal with Flange | Angled coil engineered seals are suited for low friction, small inside diameter cross sections and best at compensating for tolerance variation, and overcoming jacket wear. |

RFQ |

|

Duruseal® O: Duraz™ Elastomeric O-ring Rotary Seal | Eastomeric O-rings are best suited for chemical resistance and provide a metal free seal. |

RFQ |

|

|

Duruseal® Finger Spring with Elastomeric O ring Rotary Seal | Finger spring engineered seal are suited for sealing viscuous media as the load is applied to the edge of the sealing lips. This seal replaces conventional oil seals where a housing incases the seal. The elastomeric feature provides outer diameter sealing and helps prevent outer diameter rotation. |

RFQ |

Where are Rotary Seals used?

PTFE Duruseals® are used in many industries and applications. Here are a few examples:

- Powered surgical hand pieces

- Encoders

- Wash down seals for motors

- Gear pumps

- Centrifugal pumps

- Gas compressors

- Aircraft controls and instruments

- Vacuum feedthroughs

PTFE Rotary Seal Technical Resources

Contact our technical sales staff today to discuss your application's operating, hardware, and commercial conditions to develop the best performing seal solution.

®

Request A Quote Online Or Call Us At 866.429.2536